The Mobel 3 from Tesla might be having a biblical simplicity according to one of the analysts of Wall Street. However building any e-car still involves hundred of bolts, nuts & welds.

Cutting down on the number of finishing and fitting the issues such as significant inconsistencies which are reportedly found out by UBS.

The employees of Tesla who are reportedly going to feature on an assembly line may soon use the glass with Augmented Reality technology which is quite similar to Google’s Google Glass that will help in the production of the car, based on the filings of a new parent.

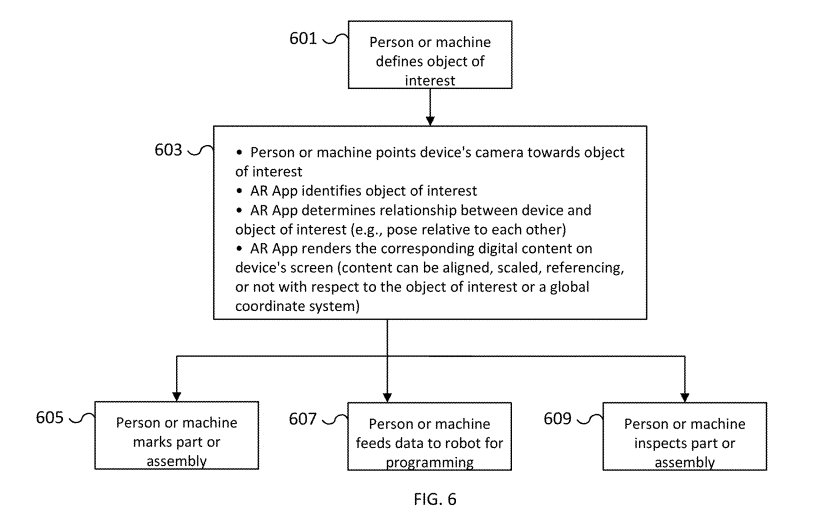

The previous week, Tesla has reportedly filed two patents related to Augmented Reality which is going to outline a very futuristic vision that is important for the relationship between robots and humans when it is about manufacturing.

The smart Augmented Reality glass will also work as safety glasses which are going to help the workers in identifying places for spot welds, joints, and many more things, according to the fillings.

Electrek has pointed out that previously Tesla has been employing the Enterprise of Google Glass during early 2016, but it isn’t clear how long was Google Glass had been utilized.

As a matter of fact, Tesla has a touch-n-go relationship when it comes to the robotics in their factories. Back in April the Chief Executive Officer of Tesla, Elon Musk has admitted that the Tesla factory which is located in Fremont, California has reportedly relied very much on the automated processes.

An analyst from Bernstein said that they believe that Tesla has been extremely ambitious with the process related to automation on the line of Model 3. And the company still hopes that they can conduct a harmonious relationship between the machines and the human this time and the company also expects the augmented reality will resolve the cooperative relationship.

Source: businessinsider